If you’re experiencing shifting problems, a spongy pedal, or signs of hydraulic failure in your clutch system, one of the first questions that comes up is: Do I need to replace both the slave and master cylinder at the same time? The short answer is—it depends, but in many cases, replacing them together is the smarter, more cost-effective move.

Your clutch master and slave cylinders work as a team. When one begins to fail, the other is often not far behind. To understand when a full replacement is necessary, let’s look at how these two components function and why replacing them together can benefit your vehicle’s performance and reliability.

Two Cylinders Working as a Team

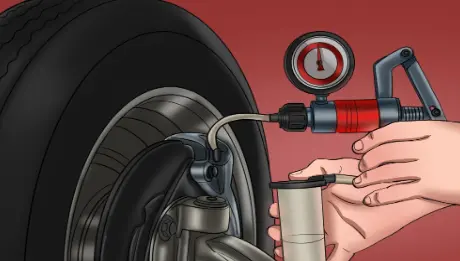

In a hydraulic clutch system, the master cylinder initiates the action. When you press the clutch pedal, the master cylinder pushes fluid through a line to the slave cylinder, which then disengages the clutch. If either of these components is leaking, worn, or damaged, the system can’t build the pressure needed for smooth engagement.

In heavy-duty trucks like the Chevrolet Silverado 3500 Clutch Master Cylinder, these components are put under tremendous pressure—especially during towing, hauling, or commercial use. If the master cylinder is failing and you only replace it without addressing a worn slave cylinder, you may still end up with inconsistent clutch performance, delayed pedal response, or difficulty shifting.

Likewise, a brand-new master cylinder can strain an aging slave cylinder, exposing any weaknesses and potentially leading to another failure soon after the first repair.

Replacing Both at Once

If one cylinder has failed due to age or wear, chances are the other is close behind—especially in older vehicles or those with higher mileage. Replacing both at the same time ensures balanced hydraulic pressure and avoids the frustration (and cost) of doing the job twice.

Here are a few reasons why replacing both cylinders at once makes sense:

-

Avoid Repeat Labor Costs: Since both cylinders are part of the same system, many repair procedures overlap. Doing both at once saves on labor charges and avoids another teardown later.

-

Restore Full System Performance: A fresh master cylinder won’t reach peak performance if the slave cylinder is still leaking or sticking—and vice versa.

-

Prevent Cross-Contamination: Old, contaminated fluid in one cylinder can degrade seals in the new part. Starting fresh with both ensures cleaner fluid and better performance.

In vehicles like the Chevrolet Camaro Clutch Master Cylinder Reservoir, maintaining pressure consistency is essential—especially in performance driving conditions. If one part is upgraded or replaced, it makes sense to bring the entire hydraulic system up to spec to avoid weak pedal feel or clutch chatter.

This principle also applies to compact trucks like the Chevrolet S10 Clutch Master Cylinder. These older vehicles often go long periods without major repairs, and by the time one cylinder goes out, the entire clutch system is often overdue for maintenance. A full replacement gives you better pedal feedback and a longer-lasting repair.

When should you replace both?

- If your vehicle has over 100,000 miles

- If you’re already replacing a worn-out clutch

- If either the master or slave has failed due to leaking, sticking, or loss of pressure

- If the system hasn’t been flushed or serviced in several years

Replacing both the clutch master and slave cylinders at once may seem like an added expense, but it’s an investment in long-term performance and reliability. You’ll enjoy smoother shifts, firmer pedal feel, and the peace of mind that comes from knowing your entire hydraulic system is working as it should.

Whether you’re driving a Silverado, a Camaro, or an S10, keeping your clutch system in sync starts with two components working together—don’t let one hold the other back.

Also Read-Enhancing Construction Site Productivity Through Wearable Tech